Organizations and Markets in Emerging Economies ISSN 2029-4581 eISSN 2345-0037

2024, vol. 15, no. 2(31), pp. 378–417 DOI: https://doi.org/10.15388/omee.2024.15.18

Unveiling Green Supply Chain Practices: A Bibliometric Analysis and Unfolding Emerging Trends

CA Rajkiran (corresponding author)

Christ Deemed to be University, India

raj.kiran@res.christuniversity.in

https://ror.org/02k949197

Shaeril Michel Almeida

Christ Deemed to be University, India

shaeril.michael.almeida@christuniversity.in

https://ror.org/02k949197

Abstract. Supply chain management is a multi-dimensional approach. Growing eco-consciousness has forced businesses to optimize operations and incorporate green practices across all the stages of supply chain in manufacturing and service sectors. Reviewing the past research literature propels us to understand its current and future prospects. Employing a systematic analysis, this research explores the intellectual structure of green supply chain practices and their connection to performance outcomes in various industries. This study covers a systematic literature review, content analysis, and bibliometric analysis on green supply chain management using VosViewer. It utilizes a PRISMA-guided screening method for identification, screening, eligibility and inclusion of literature from the literature available since 1999. The bibliometric analysis reveals key contributors, thematic clusters, prevailing theoretical frameworks, and emerging research trends in the domain of green supply chain management. China, followed by the United States and the United Kingdom, emerged as leading contributors to research in this area, driven by rapid economic growth, heightened environmental concerns, and well-established academic and industrial infrastructures. The study identifies eight thematic clusters within green supply chain management, including the triple bottom line, circular economy, and carbon emissions. The most highly cited papers within these clusters were examined for their methodologies, tools, and key findings, highlighting the prominent theories utilized in this field. Moreover, the research discusses how advanced technologies such as AI, blockchain, and big data analytics are poised to transform supply chains by enhancing decision-making and mitigating risks, thus playing a pivotal role in the future of green supply chain management.

Keywords: green supply chain management, supply chain management, sustainable supply chain management, resilience, sustainability, circular economy, reverse logistics

Received: 28/6/2024. Accepted: 4/11/2024

Copyright © 2024 CA Rajkiran, Shaeril Michel Almeida. Published by Vilnius University Press. This is an Open Access article distributed under the terms of the Creative Commons Attribution Licence, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

1. Introduction

The concept of the supply chain, as pioneered by Ransom E. Olds in the late 19th century, involved the sequential division of the production process into distinct stages. This approach, often referred to as the “division of labor,” aimed to enhance efficiency and productivity by assigning specific tasks to specialized workers (van Hoek, 1999). It was Henry Ford in 1913 who created the first moving assembly line using conveyor belts and mass-produced Model T car (Heizer, 1998). This was a breakthrough as the practice boosted production, reduced costs, and increased the efficiency of workers due to repetitive work, only necessary motion reducing accidents and better pay (Heizer, 1998). From a focus on cost optimization to a holistic approach encompassing sustainability and agility, supply chain management has significantly evolved in recent decades encompassing a broader set of activities. It has transformed from being a field of static to dynamic, positivism to interpretivism, command and control to navigational and experimental, cross-level function into cross-level transformation, from being objective to subjective (García-Arca et al., 2014; Wieland & Durach, 2021). Globalized operations have incited the need for embedding sustainability throughout the supply chain. This is due to the colossal impact of globalization on both operational efficiency and the cost of raw materials. This has not been noted only by researchers but also by entrepreneurs. Hence sustainable supply chain management has been broadly defined as the systemic, strategic coordination of the traditional business functions and the tactics across these business functions within a particular company and across businesses within the supply chain, for the purpose of improving the long-term performance of the individual companies and the supply chain as a whole (Mentzer et al., 2001). Fang et al. (2022) opined that supply chain management as a comprehensive network that starts from the procurement of raw materials and extends to the delivery of finished products to consumers. This approach emphasizes strategic cooperation across the supply chain to improve overall competitiveness and customer satisfaction. LeMay et al. (2017) viewed supply chain management as activities or functions, such as planning, sourcing, production, logistics, and customer service, which were interconnected processes that create value for customers. It is a network of organizations collaborating to deliver products or services consisting of a complex system involving multiple stakeholders and interactions. Sustainability has emerged as a paramount factor in contemporary supply chain management (SCM). This shift is characterized by a growing emphasis on green supply chains and the strategic adoption of innovative technologies such as blockchain and Industry 4.0 (Wieland & Durach, 2021). These advancements aim to enhance supply chain efficiency, transparency, and sustainability, ultimately aligning SCM practices with environmental, social, and governance (ESG) principles (Shekarian et al., 2022; J. Wang et al., 2023). Since 2021, a paramount objective in supply chain management (SCM) has been the development of resilient supply chains. This entails not only maintaining operational continuity during disruptions, but also demonstrating adaptability to evolving challenges through enhanced flexibility, redundancy, and collaborative partnerships within the supply chain network (Shahin et al., 2022).

1.1 Understanding Green Supply Chain Management

Green supply chain management (GSCM) represents a convergence of environmental science and management disciplines, applied to optimize the environmental performance of supply chains. GSCM is an evolving concept integrating environmental considerations into traditional supply chain management practices. Srivastava (2008, p. 536) defined GSCM as “integrating environmental thinking into supply-chain management, including product design, material sourcing and selection, manufacturing processes, delivery of the final product to the consumers as well as end-of-life management of the product after its useful life.” Srivastava (2008) also noted that the definition and scope of GSCM range from subjective investigative interest of the researcher. A. Sharma et al. (2024) stated that GSCM is a strategic approach that emphasizes reducing environmental impacts throughout the supply chain, from sourcing and production to distribution and end-of-life disposal. It involves practices such as eco-friendly sourcing, waste minimization, recycling, and sustainable logistics, aiming to enhance both environmental and economic performance (Jaiswal et al., 2024). Assumpção et al. (2022) was also of the opinion that integrating ecologically and socially responsible solutions is fundamental to sustainable supply chain management as these solutions are intended for the current and future generations, ultimately connecting the entire supply chain to performance objectives that prioritize long-term sustainability. Taghipour and Lu (2024) highlight the role of GSCM in promoting corporate sustainability by leveraging green innovations and sustainable practices across the supply chain. This approach not only meets regulatory requirements but also addresses increasing consumer demand for environmentally responsible products (Gong, 2023). The integration of digital technologies and circular economy principles into GSCM is also seen as critical for enhancing the resilience and sustainability of supply chains (Kamra et al., 2024). Zimon et al. (2020) state that aligning the supply chain with sustainable development goals will equip business owners to develop a more complex, stable, ethical, and robust supply chain. Seuring and Müller (2008) state that maintaining a cordial relationship with the supplier reduces the overall negative environmental and societal impact along the supply chain. Ecer and Pamucar (2020) reiterate the concept of a sustainable supply chain not only for economic reasons but also for the morale of supply chain stakeholders. According to the observation by Gangadhar and Ramakrishna Naidu (2017), critical environmental components impacting the environment can be the green design (engineering and marketing), green procurement practices (environment-friendly raw material, recycled material), and transportation (carbon dioxide reduction and minimization of fuel consumption). The integration of digital technologies and circular economy principles is also critical for improving supply chain resilience and aligning with long-term sustainability goals.

Table 1 shows the evolution of green supply chain management as the idea/principle by systematically adopting the research papers yearwise and filtered further via citation numbers.

Table 1

Green Supply Chain Management

|

Authors |

Article Title |

Interpretations of Green Supply Chain Management |

Domain |

|

van Hoek (1999) |

“From reversed logistics to green supply chains” |

Mere reverse logistics is not sufficient; instead, it needs to incorporate a new application of the footprint principle, greening in the cross-company and cross-border supply chain. |

Manufacturing |

|

Sarkis (2003) |

“A strategic decision framework for green supply chain management” |

The following elements have an interdependent relationship – product life cycle, operational life cycle, performance measures, and environmentally influential organizational policy elements. |

Manufacturing |

|

Zhu & Sarkis (2004) |

“Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises” |

It is the internal environmental management, external GSCM, investment recovery, and eco-design or design for environment practices and impacts economic, operational, and environmental performances. |

Manufacturing |

|

Zhu et al. (2005) |

“Green supply chain management in China: Pressures, practices and performance” |

GSCM is increased environmental awareness due to regulatory, competitive, and marketing pressures and drivers. GSCM indicates commitment from top-level managers and support from mid-level managers. |

Manufacturing |

|

Vachon (2007) |

“Green supply chain practices and the selection of environmental technologies” |

Environmental activities are likely to be more beneficial if conducted with the suppliers because their downstream organizations are adopting and implementing value-added technologies while addressing environmental challenges. |

Service sector |

|

Hsu & Hu, (2009) |

“Applying hazardous substance management to supplier selection using analytic network process” |

With other factors being equal, hazardous substances need to be given importance in GSCM practice. |

Manufacturing |

|

Park et al. (2010) |

“Creating integrated business and environmental value within the context of China’s circular economy and ecological modernization” |

Large and small firms play a very important role at both the firm level and at the supply chain level.

Along with cost reduction and revenue generation, it is important to incorporate resiliency and legitimacy in the Supply Chain. |

Food sector |

|

Chiou et al. (2011) |

“The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan” |

GSCM links between a greener supply chain (greening the supplier) and green innovation, or the ability to develop green products and manufacturing processes and green managerial innovation. |

Manufacturing and food sector |

|

Green et al. (2012) |

“Green supply chain management practices: Impact on performance” |

Improved environmental and economic performance will support improved operational and organizational performance. Successful adoption of GSCM practices, such as green purchasing, customer cooperation, eco design, and investment recovery, will lead to improved environmental and economic performance. |

Food sector |

|

Ahi & Searcy (2013) |

“A comparative literature analysis of definitions for green and sustainable supply chain management” |

Green Supply Chain Management (GSCM) fosters the development of coordinated inter-organizational networks. This coordination is achieved through the voluntary integration of economic, environmental, and social considerations throughout the supply chain. Key to this process are inter-organizational business systems designed to optimize the flow of materials, information, and capital across the entire product lifecycle, encompassing procurement, production, and distribution stages. In essence, GSCM seeks to achieve a multi-criteria optimization of these flows, ensuring the economic viability, environmental sustainability, and social responsibility of the supply chain. |

Multi-Industry |

|

Govindan et al. (2014) |

“Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process” |

GSCM is an effort to integrate environmental parameters or requirements with supply chain management systems. Green Supply Chain Management modifies the traditional supply chain management to incorporate environmental sustainability, particularly through green procurement strategies. |

Multi-Industry |

|

Li et al. (2016) |

“Pricing policies of a competitive dual-channel green supply chain” |

The concept of GSCM compels the supply chain members to reconsider various problems such as inventory decisions, product innovation, returns management, reverse logistics design, and coordination between channel players, to improve the environmental and economic performance of organizations. |

Manufacturing and retail sector |

|

Genovese et al. (2017) |

“Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications” |

GSCM is the integration of environmental concerns into organizations by minimizing materials or reducing unintended negative consequences of production and consumption processes. This involves taking a holistic view of the entire product supply chain to establish greener and more sustainable production systems based on reusing and remanufacturing materials. |

Food and chemical industry |

|

Zaid et al. (2018) |

“The impact of green human resource management and green supply chain management practices on sustainable performance: An empirical study” |

It is a set of practices that aim to integrate environmental concerns into supply chain management processes. GSCM encompasses various dimensions such as environmental sustainability, social responsibility, and economic viability. |

Manufacturing |

|

Saberi et al. (2019) |

“Blockchain technology and its relationships to sustainable supply chain management” |

GSCM involves the implementation of environmentally friendly processes and technologies to minimize the environmental impact of supply chain activities. |

Food and beverage industry |

|

Yadav et al. (2020) |

“A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case” |

Green practices are used to penetrate sustainability effectively through various practices such as lean, green, circular, and industry 4.0. |

Automotive industry |

|

Kouhizadeh et al. (2021) |

“Blockchain technology and the sustainable supply chain: Theoretically exploring adoption barriers” |

Green Supply Chain Management practice emphasizes sustainability by balancing environmental, social, and business dimensions, also known as the triple bottom line. This approach is driven by social, competitive, and regulatory reasons, and it involves verifying products for sustainability and providing accessible product information to consumers. |

Energy, food, and manufacturing |

|

Parmentola et al. (2022) |

“Is blockchain able to enhance environmental sustainability? A systematic review and research agenda from the perspective of Sustainable Development Goals (SDGs)” |

GSCM focuses on business, commerce, circular economy, competitiveness, knowledge, cost reduction, economic analysis, decentralization, design, digital economy, digitalization, distributed ledger, governance, green manufacturing, Industry 4.0, information management, innovation, logistics, sustainability, traceability transparency, stakeholder, empirical analysis, integrated approach, and smart contracts. |

Energy and utilities, fashion, fintech/cryptocurrency, logistics and supply chain, manufacturing/industry, transportation |

|

Jraisat et al. (2023) |

“Triads in sustainable supply-chain perspective: Why is a collaboration mechanism needed?” |

The Green Supply Chain Management is about managing material, information, and capital flows while considering economic, environmental, and social dimensions of sustainability. Sustainability benefits by engaging in collaborative activities and assets with minimal uncertainties, thus contributing to economic, social, and environmental outcomes in supply chains. |

Agriculture |

2. Justification of Research

The study identifies critical challenges hindering progress and proposes promising avenues for further research. It delves into the existing social and intellectual landscape of GSCM, offering a valuable resource for aspiring researchers. It introduces them to novel research topics, diverse implementation contexts, and potential collaborative opportunities.

The review underscores the significant societal implications of the green supply chain management (GSCM) across various industries. It effectively delineates industries with the highest and lowest levels of GSCM research. Notably, the automotive industry emerges as a prominent sector with substantial GSCM research activity. Conversely, the fast-food sector is identified as an area where GSCM research is relatively underrepresented (Genovese et al., 2017; Siddhi & Chitnis, 2019). GSCM practices directly influence environmental sustainability by promoting efficient resource utilization across supply chain. This furthermore enhances organizational efficiency and additionally minimizes negative ecological effects. The research highlights the multifaceted benefits of GSCM for organizational performance, encompassing economic, environmental, and operational aspects.

By systematically synthesizing existing research, the study identifies recurring trends and sheds light on the factors shaping supply chain practices in various industries. This comprehensive examination of the current state of GSCM offers valuable insights for future research endeavors. The identified research gaps frame the research objectives. This study investigates the following research questions:

RQ1. Which authors and countries are the most influential in the field of green supply chain management research, as evidenced by their citation impact?

RQ2. What are the key thematic clusters and sub-themes within the scholarly discourse on the research on the green supply chain management (GSCM)?

RQ3. Which theoretical frameworks and perspectives have been predominantly employed in the field of GSCM research?

RQ4. What can be the future trajectory for the green supply chain management?

A systematic literature review leverages a rigorous and transparent approach to identify relevant studies. This methodology prioritizes a comprehensive search strategy with clear selection process documentation. By doing so, a systematic literature review ensures transparency and allows readers to critically evaluate the review findings within the context of the existing body of evidence. Cabrera et al. (2023) introduced a System Literature Review (SLR) process, a structured approach with clear evaluation guidelines, and outlined three types of searches in the SLR method: scholarly, public, and hasty (Bhandari, 2024; Rana et al., 2022). This paper reviewed the application of several established frameworks, such as the ADO (antecedents, decisions, and outcomes) and the TCCM (theory, context, characteristics, and methodology) approaches, in the development of Systematic Literature Review (SLR) articles by Paul et al. (2023), and PRISMA (preferred reporting items for systematic reviews and meta-analysis). The PRISMA framework enhances the quality of systematic literature reviews by ensuring transparent and rigorous reporting through a detailed checklist (Bhandari, 2024). The PRISMA framework offers a flexible approach, well-suited for reporting systematic reviews that evaluate interventions, while also adaptable to studies with broader research objectives (Rana et al., 2022).

The research employed technology-assisted methods to expedite the analysis of a vast amount of literature on green supply chain practices aiding in organizing the data more efficiently and using the data for further research effectively. To simplify bibliometric analysis and improve the quality of theoretical reference selection, Smart Bibliometrics has been used—a tool designed to introduce intelligence, dynamism, and agility to the scientific writing process. The uniqueness of this methodology comes from the combination of two important factors used throughout the bibliometric analysis procedure: the use of a performance measure for classifying scientific papers; and strategically created dynamic visualizations (Pessin et al., 2022). Moreover, to enhance robust and credible analysis, articles were sourced from the Scopus database. The study presents the results of a bibliometric analysis performed for the period from 1999 to 2024.

The research article will benefit industry practitioners and academicians by contributing to overall intellectual analysis. The current research proposition, structure, and evolution of various themes can be deciphered from the research study. It also suggests the future emerging trends in the green supply chain management. The study has incorporated SLR and bibliometric analysis to answer pre-defined objectives targeted towards answering the research questions.

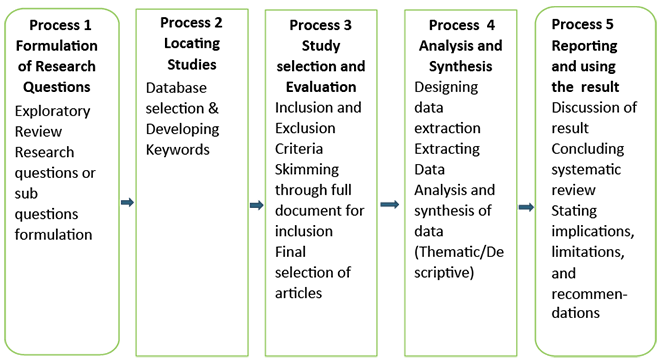

Figure 1

Systematic Review Process

Note. According to Bhandari (2024) and Denyer and Tranfield (2009).

3. Methodology

As stated earlier, there are multiple ways of conducting the literature review: SLR, meta-analysis, bibliometric analysis and content analysis (Duque-Uribe et al., 2019). Figure 1 shows the main stages of the research. The first step involves procedure recommendations (Denyer & Tranfield, 2009). The following step is to extract reliable research articles from an authentic database. It is crucial in bibliometric analysis to choose the right database. Scopus is considered one of the largest and most reliable

Table 2

Preparing for Data Analysis

|

Keywords for Search |

Green Supply Chain Management AND Sustainable Supply Chain Management OR GSCM |

|

Document Type |

Journal Articles |

|

Language |

English |

|

Time Span |

1999–2024 |

|

Subject Category |

Business Management, Commerce, Social Science |

Table 3

Article Selection Criteria

|

Criteria for inclusion |

Criteria for exclusion |

|

Green supply chain management and sustainable supply chain management articles |

Conference Papers |

|

Refereed academic Scopus journals |

Book chapters, book reviews |

|

Articles published in English between 1999 and 2004 |

Articles in press |

Figure 2

PRISMA Framework

Note. Adapted from Moher et al. (2009).

research databases. A comparative analysis between WoS and Scopus evaluates research that may create disciplinary biases within research evaluation frameworks, potentially favoring traditionally quantitative fields (Mongeon & Paul-Hus, 2016). Moreover, Scopus has extensive indexing, which includes several academic articles, conference papers, books, and even patents, enabling a thorough examination of the investigation outcomes (Mongeon & Paul-Hus, 2016; Pessin et al., 2022).The interdisciplinary nature of Scopus also makes it particularly appropriate for our investigation, which tries to examine the confluence of several fields (Pejic Bach & Cerpa, 2019). Elsevier asserts that Scopus is comprehensive and allows for a thorough method of analytics research (Aria & Cuccurullo, 2017). This multidisciplinary inclusion increases the relevance and utility of analysis by capturing a wider viewpoint on the issue.

Figure 2 illustrates the PRISMA framework for a systematic literature review, detailing the sequential steps of the article selection process, as discussed below.

• Identification: The initial step involves identifying articles addressing the core themes of the review relevant to the topic. It indicates that a Scopus database was used to search for articles using keywords. This search yielded 7,792 references.

• Screening: Following identification, the retrieved articles are screened to exclude irrelevant studies and remove duplicates. Of the 7,792 references identified, 3,397 met the inclusion criteria and were deemed eligible for review.

• Eligibility: The articles that remain after screening, undergo an eligibility check to assess if they adhere to the pre-defined inclusion requirements of the review.

• Inclusion: Articles that meet the predetermined inclusion criteria are incorporated into the final systematic review, resulting in the inclusion of 3,397 articles for the SLR.

4. Results

4.1. Descriptive Analysis

4.1.A. Publication Trends

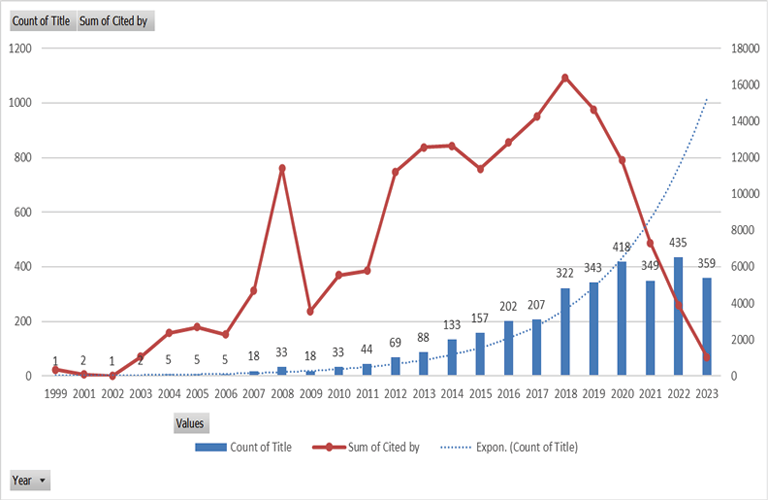

Figure 3 illustrates a marked increase in the number of published titles, as indicated by the steep upward trajectory of the “Count of Title” (blue line). In contrast, the “Sum of Cited by” (red line) exhibits a more gradual rise, suggesting that while publication volume surged, citation accumulation was comparatively slower. The dotted line, representing an exponential fit to the “Count of Title” data, confirms that publication growth follows an exponential trend. This pattern reflects a vibrant and expanding research environment; however, the slower citation growth underscores the need to consider additional metrics beyond publication count to assess research impact effectively.

Figure 3

Publication and Citation Dynamics Across Years

4.1.B. Key Contributors to the Literature (By Citation Frequency)

Table 4

Leading Scholars in the Arena of GSCM

|

Author Details |

Year |

No. of |

Main Arguments |

Future Research |

|

Seuring & Müller (2008) |

2008 |

8058 |

Most articles dealt with environmental problems, with a smaller number focusing on social issues, and even fewer integrating both environmental and social dimensions. |

The areas of further research should focus on issues related to People or social performance of the Triple Bottom Line approach and also on the amalgamation of 3 dimensions of sustainable development (People, Profit & Planet). |

|

Govindan et al. (2013a) |

2013 |

4945 |

The development of a fuzzy multi-criteria approach for measuring the sustainability performance of suppliers based on the Triple Bottom Line (TBL) approach |

The promise of real-time evaluation models that seamlessly combine supplier selection with ongoing monitoring and analysis. |

|

Zhu & Sarkis (2004) |

2004 |

1899 |

The research explores the moderating effects of quality management practices and just-in-time (JIT) practices on the relationship between GSCM and economic performance. |

Potential for investigating the long-term effects of GSCM practices indicating the need for longitudinal studies to understand the sustainability of these practices over time |

|

Dubey et al. (2015) |

2015 |

1879 |

Impacts of supplier relationship management (SRM) and total quality management (TQM) on environmental performance under the influence of leadership and the moderation effect of institutional pressures |

Exploring more dimensions under social and economic variants of institutional pressures |

|

Saberi et al. (2019) |

2019 |

1501 |

Emphasizing the need for better information sharing and verifiability due to inefficient transactions, fraud, and poorly performing supply chains; Identification of barriers hindering blockchain technology adoption; The need for interdisciplinary investigations to build theories and designs for blockchain technology. |

Exploring the potential of blockchain technology to streamline and enhance various business processes beyond cryptocurrency. Industry consortia focused on creating standardized frameworks for deploying blockchain solutions; organizations to develop standards and provide practical performance measurement on blockchain technology implementation |

|

Basiri & Heydari (2017) |

2017 |

559 |

The proposed collaboration model is capable of enhancing the supply chain profit fairly close to the centralized model and ensures higher profits for both channel members than decentralized decision-making. |

Examining the perspectives of suppliers, logistics, and retailers investigate thoroughly the challenges and opportunities in implementing the proposed collaboration model in real-world supply chains |

|

Khan et al. (2019) |

2019 |

531 |

Emphasis on the need to integrate sustainability factors, including economic, environmental, and social sustainability, with green logistics indices at a macro level; |

Proposes conducting comparative research between South Asian trade blocks and other countries and extending the study to ASEAN countries. |

|

Zhu et al. (2008) |

2008 |

394 |

Development of prescriptive models for measures of GSCM practices implementation, the advantages of using convenience and random surveys in data collection, and the potential for future research to focus on measurement models for GSCM performance improvement and comparisons of GSCM practices implementation among different countries. |

Cooperation within reverse logistics networks and customer engagement in product take-back programs for recycling; Validating the measurement scale and the need for future studies to refine and test the measurement items. |

|

Jermsittiparsert et al. (2019) |

2019 |

277 |

The moderating role of total quality management (TQM) practices was examined, with the direct relationship between TQM practices and sustainable performance being accepted on statistical grounds. |

Examine the impact of TQM on social and economic environment |

|

Kusi-Sarpong et al. (2019) |

2019 |

233 |

Insights into the strategic managerial guidance for developing sustainability innovation in manufacturing supply chains, emphasizing the high ranking of environmental criteria and the implications for research and practice. |

Broader empirical and longitudinal studies to determine if the importance of sustainable innovation criteria may change over time; Utilizing other multi-criteria decision-making (MCDM) techniques to investigate the criteria weights in both models and compare their final outputs. |

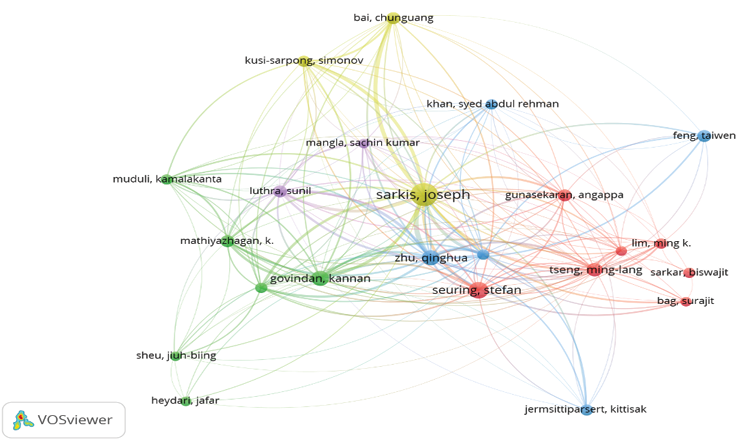

Fig. 4 presents a visualization generated by Vosviewer software depicting the ten most prominent authors in a specific field based on their global citation counts. The network layout employs lines to connect these authors, with the thickness of each line signifying the strength of the co-citation link between them. In essence, the authors who are frequently referenced together within the academic literature are linked by thicker lines.

Figure 4

Prominent Authors Based on Global Citation

4.1.C

Table 5

Geographic Distribution of Scholarly Output

|

Sl. |

Country Name |

No. of Articles Published |

Top Global |

Global Landscape of Research Productivity (Percentage) (N=3,397) |

|

1 |

China |

659 |

34936 |

19.4 |

|

2 |

United States |

415 |

43326 |

12.22 |

|

3 |

United Kingdom |

373 |

25742 |

10.98 |

|

4 |

India |

459 |

20841 |

13.51 |

|

5 |

Germany |

154 |

14606 |

4.53 |

|

6 |

Canada |

103 |

13294 |

3.03 |

|

7 |

Taiwan |

145 |

11253 |

4.27 |

|

8 |

Hong Kong |

60 |

8271 |

1.77 |

|

9 |

Iran |

246 |

10577 |

7.24 |

|

10 |

Italy |

143 |

7377 |

4.21 |

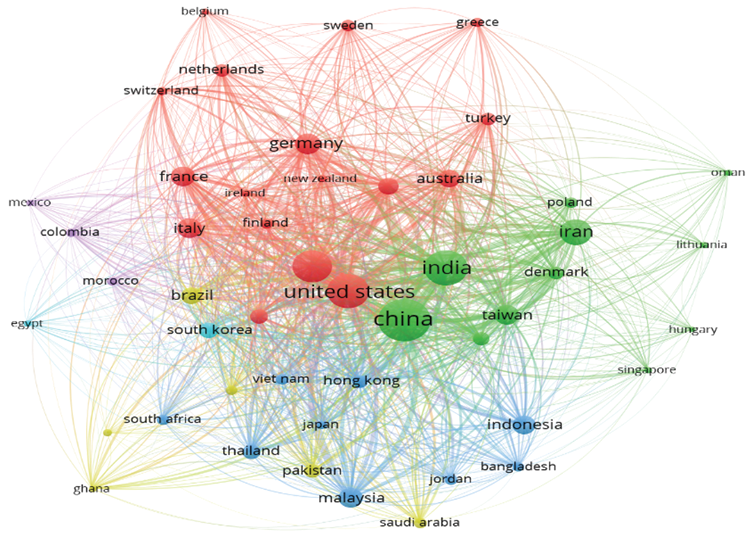

Figure 5

Distribution of Scholarly Articles by Country

The analysis of scholarly articles reveals China as the top publisher (659 articles) with significant global impact (34,936 citations). The US, though second in publishing (415 articles), boasts the highest average citation count (43,326), signifying lasting research impact. UK (373 articles) and India (459 articles) demonstrate strong publishing presence, but India’s citation count (20,841) suggests potential for higher impact. Other countries like Germany (154 articles) contribute impactful research (14,606 citations), highlighting the diversity of the global research landscape. This analysis emphasizes the importance of examining both publication volume and citation metrics to assess a country’s research influence. China leads in scholarly publications but lags in citations compared to the United States, which exhibits high-impact research. The United Kingdom and India demonstrate significant publication activity, while Germany’s smaller output is offset by influential research. These findings emphasize the importance of considering both publication quantity and citation metrics for a comprehensive assessment of research influence.

4.2. Mapping Conceptual Overlap in GSCM: A Keyword Co-occurrence Approach

To understand the themes and sub-themes, co-occurrence of keywords analysis was conducted. The intellectual structure can be classified into 8 clusters. Analysis of 956 keywords yielded a valuable set of 37 terms that exhibited strong co-occurrence, appearing together at least three times. A visual representation of keyword relationships can be employed to identify thematic clusters within a body of research (Srivastava et al., 2020). As illustrated in Figure 4, keywords like “Green Supply Chain Management,” “Supply Chain Management,” “Sustainable Supply Chain Management,” and “Sustainability” exhibit the strongest co-occurrence patterns. This suggests that these terms are frequently searched together in the context of organizational success research, potentially indicating a high degree of conceptual overlap (Table 6).

Bibliometric Coupling

Kessler (1963) laid the groundwork for the concept of bibliographic coupling. The VOSviewer software uses the term “document” as the unit of measurement while doing co-citation analysis. A group of papers that share a research topic and a relationship between two articles may be allowed by the bibliometric coupling when there is a large percentage of similar keywords, descriptions, and citations between the two co-citation analysis revealing a similar link between the articles (Weinberg, 1974; Xu et al., 2018).

Figure 6

Keywords Co-occurrence of Themes Network

Note. Red – Green Supply Chain Management, Blue – Supply Chain Management, Purple – Sustainable Supply Chains, Dark Green – Sustainable Supply Chain Management.

4.2.A. Key Thematic Clusters And Sub-Themes Cluster Formed

Table 6

Green Supply Chain Management Research Clusters: Sub-themes (Motifs) and Associated Researchers

|

Author |

Cluster No. |

Sub Theme (Motifs) |

Theme |

|

Zhu & Sarkis (2004) |

1 |

Impact of GSCM practices on organizations |

Green SCM, Sustainable SCM |

|

Zhu et al. (2008) |

1 |

Developing and validation measurement scale for GSCM |

Green SCM, Sustainable SCM |

|

Green et al. (2012) |

1 |

Impact of GSCM practices on economic performance |

Green SCM, Sustainable SCM |

|

Ahi & Searcy (2013) |

1 |

Key dimensions of GSCM |

Green SCM, Sustainable SCM |

|

Zhu et al. (2007) |

1 |

Environmental sustainability |

Green SCM, Sustainable SCM |

|

Zhu & Sarkis (2007) |

1 |

Process of greening supplier, product & impact |

Green SCM, Sustainable SCM |

|

Chiou et al. (2011) |

1 |

Product lifecycle impact on GSCM |

Green SCM, Sustainable SCM |

|

Genovese et al. (2017) |

1 |

Drivers or pressures of GSCM |

Green SCM, Sustainable SCM |

|

Zhu & Sarkis (2006) |

1 |

Green supplier selection and order allocation |

Green SCM, Sustainable SCM |

|

Wu & Pagell (2011) |

1 |

Barriers in implementing |

Green SCM, Sustainable SCM |

|

Kannan et al. (2013) |

1 |

Environmental Management Systems |

Green SCM, Sustainable SCM |

|

Mathiyazhagan et al. (2013) |

1 |

Coordination among suppliers |

Green SCM, Sustainable SCM |

|

Darnall et al. (2008) |

1 |

Supply Chain Network Design |

Green SCM, Sustainable SCM |

|

Ghosh & Shah (2015) |

2 |

Integration of GSCM with circular economy |

Circular economy, Triple Bottom Line |

|

Wang et al. (2011) |

2 |

Obstacles in implementing GSCM and assign ranks to solutions |

Circular economy, Triple Bottom Line |

|

Genovese et al. (2017) |

2 |

Integration of sustainability in SCM |

Circular economy, Triple Bottom Line |

|

Yadav et al. (2020) |

2 |

Drivers to adopt sustainable manufacturing |

Circular economy, Triple Bottom Line |

|

Winter & Knemeyer (2013) |

2 |

Circular production systems in the construction industry |

Circular economy, Triple Bottom Line |

|

Moktadir et al. (2018) |

2 |

Levers to overcome challenges in the circular economy |

Circular economy, Triple Bottom Line |

|

Nasir et al. (2017) |

2 |

Stake holder pressure |

Circular economy, Triple Bottom Line |

|

Bressanelli et al. (2019) |

2 |

Blended business with sustainability along SCM |

Circular economy, Triple Bottom Line |

|

Meixell & Luoma (2015a) |

2 |

Institutional pressure, sustainability |

Circular economy, Triple Bottom Line |

|

Franco (2017) |

2 |

Circular chain practices |

Circular economy, Triple Bottom Line |

|

Kannan (2018) |

2 |

Criteria to select supplier – Critical success factors |

Circular economy, Triple Bottom Line |

|

2 |

Logistics operations along with GSCM practices |

Circular economy, Triple Bottom Line |

|

|

Gold et al. (2013) |

2 |

Integration of poor communities in Value creation |

Circular economy, Triple Bottom Line |

|

Giovanni (2012) |

2 |

Internal environmental and environmental management on Triple Bottom Line |

Circular economy, Triple Bottom Line |

|

Batista et al. (2018) |

2 |

Identification of different circular supply chains |

Circular economy, Triple Bottom Line |

|

Chaabane et al. (2012) |

3 |

Tradeoff between economic & environmental objectives |

Carbon Emission |

|

Srivastava (2008) |

3 |

Decision making in network configuration |

Carbon Emission |

|

Sheu et al. (2005) |

3 |

Integrated logistics operational problems |

Carbon Emission |

|

van Hoek (1999) |

3 |

Green supply chains |

Carbon Emission |

|

Elhedhli & Merrick (2012) |

3 |

Strategic location and logistical cost |

Carbon Emission |

|

Lu et al. (2007) |

3 |

Supplier evaluation |

Carbon Emission |

|

Hsu et al. (2013) |

3 |

Drivers influencing GSCM |

Carbon Emission |

|

Meixell & Luoma (2015a) |

3 |

Stakeholder pressure |

Carbon Emission |

|

Sharma et al. (2010a) |

3 |

B2B marketing |

Carbon Emission |

|

Zhao et al. (2017) |

3 |

Minimizing risk, economic cost |

Carbon Emission |

|

Beske & Seuring (2014) |

4 |

Sustainability performance |

Risk Management, Resilience |

|

Rostamzadeh et al. (2018) |

4 |

Evaluation of sustainable SCM risk |

Risk Management, Resilience |

|

Abdel-Basset & Mohamed (2020) |

4 |

Identification of risk factors and rank |

Risk Management, Resilience |

|

Roehrich et al. (2014) |

4 |

Reputational risk exposure |

Risk Management, Resilience |

|

Freise & Seuring (2015) |

4 |

Moderating effect of social and environmental sustainability practices |

Risk Management, Resilience |

|

Gouda & Saranga (2018) |

4 |

Preventive actions for failures of SSCM |

Risk Management, Resilience |

|

Valinejad & Rahmani (2018) |

4 |

Managerial implications for risk |

Risk Management, Resilience |

|

Rehman Khan & Yu (2021) |

4 |

Inter-relations between risk elements |

Risk Management, Resilience |

|

Fernando et al. (2018) |

4 |

Managing project success |

Risk Management, Resilience |

|

Ozturkoglu et al. (2019) |

4 |

Sustainable risk assessment |

Risk Management, Resilience |

|

Meixell & Luoma (2015) |

5 |

Stakeholder pressure influencing management decisions |

Green Purchasing, Green Manufacturing |

|

Sharma et al. (2017) |

5 |

Sub performance indicators of GSCM |

Green Purchasing, Green Manufacturing |

|

Li et al. (2016) |

5 |

Managements success factors due to greening |

Green Purchasing, Green Manufacturing |

|

Xu & Gursoy (2015) |

5 |

Customer satisfaction, willingness to pay and loyalty |

Green Purchasing, Green Manufacturing |

|

Scur & Barbosa (2017) |

5 |

Commitment of organization |

Green Purchasing, Green Manufacturing |

|

Yu et al. (2019) |

5 |

Environmental performance |

Green Purchasing, Green Manufacturing |

|

Khan et al. (2017) |

5 |

Green collaboration |

Green Purchasing, Green Manufacturing |

|

Famiyeh et al. (2018) |

5 |

Operational competitive cost |

Green Purchasing, Green Manufacturing |

|

Bazan et al. (2017) |

6 |

Coordination mechanisms |

Reverse Logistics, Remanufacturing |

|

Wu (2013) |

6 |

Competitive pricing and product designs |

Reverse Logistics, Remanufacturing |

|

Chung & Wee (2011) |

6 |

Inventory policy integrated with technology |

Reverse Logistics, Remanufacturing |

|

Abdallah et al. (2012) |

6 |

Fixed cost, carrying inventory cost |

Reverse Logistics, Remanufacturing |

|

Bose & Pal (2012) |

6 |

Stock prices of the firm |

Reverse Logistics, Remanufacturing |

|

Chen & Ulya (2019) |

6 |

Reward-penalty mechanism governmental intervention |

Reverse Logistics, Remanufacturing |

|

Khor & Hazen (2017) |

6 |

Information asymmetry on consumers |

Reverse Logistics, Remanufacturing |

|

Frota Neto et al. (2016) |

6 |

Managerial adaptability |

Reverse Logistics, Remanufacturing |

|

Abbey & Guide (2018) |

6 |

Managerial adaptability |

Reverse Logistics, Remanufacturing |

|

6 |

Differences in manufacturing and service sector implementations |

Reverse Logistics, Remanufacturing |

|

|

Zhu et al. (2005) |

7 |

GSCM Practices |

Green Marketing |

|

Hong & Guo (2019) |

7 |

Cooperation of stakeholders |

Green Marketing |

|

Sharma et al. (2010b) |

7 |

B2B implementation |

Green Marketing |

|

Chan et al. (2012) |

7 |

Greener approach in business |

Green Marketing |

|

Sharma & Iyer (2012) |

7 |

Resource-constrained product development |

Green Marketing |

|

Liu et al. (2012) |

7 |

Managerial decision making |

Green Marketing |

|

Lee & Lam (2012) |

7 |

Sustainability of industrial operational management |

Green Marketing |

|

Brindley & Oxborrow (2014) |

7 |

Supply chain drivers and managerial drivers |

Green Marketing |

|

Kirchoff et al. (2011) |

7 |

Integration between firms demand and stake holder pressure |

Green Marketing |

|

Mondal & Giri (2020) |

7 |

Optimal strategies and profitability |

Green Marketing |

|

Govindan et al. (2013b) |

8 |

Supplier selection based on TBL |

Corporate Social Responsibility |

|

Tate et al. (2019) |

8 |

Supply chain factoring into TBL |

Corporate Social Responsibility |

|

Morali & Searcy (2013) |

8 |

Corporations utilize the collaborative paradigm |

Corporate Social Responsibility |

|

Sajjad et al. (2015) |

8 |

Motivators for SSCM and Stakeholder management |

Corporate Social Responsibility |

|

Rueda et al. (2017a) |

8 |

Strategies and motivations behind corporate investment |

Corporate Social Responsibility |

|

Li et al. (2014) |

8 |

Sustainable governance management and practices |

Corporate Social Responsibility |

|

Wang et al. (2020) |

8 |

Big data analytics |

Corporate Social Responsibility |

|

Mishra (2017) |

8 |

Green human resource practices |

Corporate Social Responsibility |

|

Liu et al. (2019) |

8 |

Governmental interference |

Corporate Social Responsibility |

|

Ortas et al. (2014) |

8 |

Stakeholder evaluation and environmental policy outcomes |

Corporate Social Responsibility |

4.2.B. Analysis of Clusters Formed

Cluster 1: Green Supply Chain Management and Sustainable Supply Chain Management. Zhu and Sarkis (2004) established a positive strong correlation between GSCM practices and economic performance, Zhu and Sarkis (2007) found a different outcome for Chinese automobile companies. Despite strong GSCM implementation, their economic performance showed weak or no improvement. Similar inconsistencies emerge regarding environmental performance. Zhu and Sarkis (2004) found a positive impact of GSCM practices, whereas Zhu and Sarkis (2006) reported only slight improvement for Chinese automobile companies. Studies by Zhu and Sarkis (2006) and Wu and Pagell (2011) highlighted the varying pressures for GSCM implementation across industries. Zhu and Sarkis (2006) identified regulations as the most prevalent pressure, while Wu and Pagell (2011) explored how companies within different industries pursue sustainable business practices that ensure profitability without compromising environmental well-being. These contrasting findings suggest that the effectiveness of GSCM practices is not universal. Factors like industry context, the nature of pressures driving implementation, and the specific focus of GSCM efforts (e.g., eco-design versus investment recovery) can all influence the outcomes. Future research efforts are warranted to gain a deeper understanding of these nuances and optimize GSCM implementation strategies for different contexts.

Cluster 2: Triple Bottom Line and Circular Economy. Winter and Knemeyer (2013) revealed a potential bias towards the environmental dimension, highlighting the need for a more holistic approach encompassing social, economic, and environmental factors (complementary to Nasir et al. (2017), who compared the environmental impacts of different supply chains). Bressanelli et al. (2019) identified challenges in redesigning supply chains for circularity, while Genovese et al. (2017) explored integrating green practices with circular economy principles, which are the contrasting viewpoints suggesting both potential and roadblocks for circular economy implementation. Franco (2017) suggested that industry key players drive demand for circular products, not necessarily consumer awareness, contrasting with Batista et al. (2018), who found increasing publications on circular supply chains, indicating growing concern. This implies a need for broader consumer education alongside industry efforts. De Giovanni (2012) found no significant link between environmental and economic performance, whereas Park et al. (2010) suggested that incorporating environmental practices leads to a sustainable competitive advantage.

Cluster 3: Carbon Emission and Logistics. Chaabane et al. (2012) proposed a comprehensive structure for designing sustainable supply chains, incorporating trade-offs between economic and environmental objectives. This contrasts with studies by Sheu et al. (2005) and Elhedhli and Merrick (2012), where environmental improvements like reduced carbon emissions or improved waste management can also lead to economic benefits. Hsu et al. (2013) researched the green initiatives in developing countries and found limited GSC initiatives in emerging economies like Malaysia and Indonesia; meanwhile, studies of Srivastava (2008) highlighted the potential profitability of reverse logistics networks for companies, which can incentivize sustainable practices. The impact of regulations was studied by Hsu et al. (2013), where researchers identified weak regulatory measures as a driver for green supply chain areas. Elhedhli and Merrick (2012) demonstrated how stricter environmental regulations can influence supply chain design and planning. These contrasting findings suggest that the economic and environmental impacts of GSCM practices can vary depending on factors like industry context, regulatory environment, and specific green initiatives undertaken.

Cluster 4: Risk Management and Resilience. Research by Roehrich et al. (2014), Abdel-Basset and Mohamed (2020) and Rostamzadeh et al. (2018) that focused on identifying and ranking specific risk factors using various models revealed that reputational risk is a major driver for sustainable supply chain risk management. The study of the impact of sustainability practices by Gouda and Saranga (2018) found a significant positive association between sustainability practices and risk perception, suggesting that sustainability efforts can reduce overall risk. In contrast, Freise and Seuring (2015) focused on legal compliance and stakeholder pressure as primary drivers for managing environmental and social risks. The study by Valinejad and Rahmani (2018) identified and categorized sustainability risks specific to the telecommunication, while Khan et al. (2021) did similar research in Halal food industries.

Cluster 5: Green Purchasing and Green Manufacturing. Hsu et al. (2013) found limited GSCM adoption in developing countries like Malaysia, Scur and Barbosa (2017) identify green practices being implemented by home appliance manufacturers in Brazil, albeit at varying stages. This suggests that GSCM adoption may be influenced by regional development. Meixell and Luoma (2015) highlights the varying influence of stakeholders (customers, competitors, etc.) on different sustainability aspects (environmental vs social). This contrasts with the findings of Khan et al. (2017) on the impact of GSCM practices on overall enterprise performance in Chinese manufacturing. V. K. Sharma et al. (2017) propose performance measurement variables for the agro-industry, whereas Xu and Gursoy (2015) emphasize the need for a comprehensive view in all the other industries.

Cluster 6: Remanufacturing and Reverse Logistics. Chung and Wee (2011) state that inventory decisions involving new technology, remanufacturing ratios, and holding costs all influence inventory control in green supply chains with short-lived products. Abdallah et al. (2012) found that the transportation costs favor decentralized structures, while inventory costs favor centralized ones. According to Chen and Ulya (2019), the value of recovered materials significantly impacts the economic feasibility of closed-loop networks. They also observed the government incentives to explore how government reward-penalty mechanisms can positively influence green closed-loop supply chains by encouraging green practices from both retailers and manufacturers. While Khor and Hazen (2017) found that consumer attitudes and perceptions can influence the reason to purchase products that are remanufactured, research by Frota Neto et al. (2016) suggests a general consumer tolerance for a price markup for new products. However, this price sensitivity appears to diminish when considering high-quality remanufactured goods. The industry variations as observed by Chiarini (2014) found that the strategies for developing sustainable supply chains, such as implementing ISO 14001 or adopting waste management systems, can vary between manufacturing and service sectors.

Cluster 7: Green Marketing. Hong and Guo (2019)researched into consumer influence and found consumer environmental consciousness to be a key driver for green marketing and product design. Zhu et al. (2005) suggest a lag between environmental pressures and GSCM adoption in China. Sharma et al. (2010b) highlight the marketing strategies and the role of marketing in achieving environmental sustainability, while Brindley and Oxborrow (2014) identified the gap between organizational and market demands for sustainable products. The studies of integration challenges conducted by Chan et al. (2012) and Liu et al. (2012) emphasize the need for a holistic approach to integrating green marketing and GSCM, highlighting challenges in information flow, resource allocation, and performance measurement (Lee & Lam, 2012). The research into financial benefits by Mondal and Giri (2020) suggests that green marketing and GSCM practices may lead to intensified competitive advantages and improved profitability; whilst Zhu et al. (2005) find limited performance improvements in some areas despite increased environmental awareness.

Cluster 8: Corporate Social Responsibility. Mathiyazhagan et al. (2013) and Tate et al. (2009) explored the integration of sustainability principles with supplier relationship management and corporate social responsibility initiatives. By contrast, Sajjad et al. (2015) highlighted factors like top management values, risk reduction, and stakeholder pressure as motivators for adopting sustainable supply chain management (SSCM). The study of integration challenges by Morali and Searcy (2013) identified the need for collaboration among stakeholders, particularly suppliers, for effective SSCM implementation. Similarly, Y. Li et al. (2014) emphasized the vital strengthening of core impact and stakeholder collaboration in fast fashion supply chains. The financial performance of Ortas et al. (2014) suggests a positive but complex financial linkage between sustainable supply chain performance and key metrics. C. Wang et al. (2020) found that internal CSR practices have a direct positive impact on GSCM adoption. Additionally, Y. Liu et al. (2019) highlight that a moderate level of government CSR subsidies can improve supply chain performance and social welfare.

4.3. Theory Development

Based on the literature review, there are 10 theories identified which are extensively used in the field of GSCM research. Among them, institutional theory was one of the pioneering theories used to assess the GSCM practices and is still widely incorporated in research studies. Institutional theory facilitated the organizations in understanding the motivations, predicting diffusion, and developing the strategies keeping the coercive, normative, and mimetic in adopting the practices. Fuzzy set theory offers a valuable framework for addressing this challenge due to its ability to handle imprecise and subjective information. It aids making better decisions, coordinating among suppliers, supplier selection, performance evaluation, risk assessment, prioritization, and trade-offs. Game theory allows the organization to model interactions between various players in a supply chain, such as manufacturers, suppliers, and other stakeholders. Each player has their objectives (e.g., profit maximization) and can make strategic decisions (e.g., investing in green technology). The game theory facilitates identifying Nash equilibrium, analysing strategic incentives, and sustainable pricing strategies but it is a complex model. The coordination theory aids in collaborative planning, forecasting, and replenishment leading to optimized production runs and reduced waste as well as better supplier relationship management and green contract design. For smaller organizations, grey theory facilitates handling uncertainty, dynamic system modeling, and small data analysis. While it may not replace traditional data-driven methods, its ability to handle uncertainty and leverage limited data makes it a useful tool for early-stage decision-making, risk assessment, and performance forecasting in the context of GSCM. Agency theory offers a valuable framework for understanding from cost considerations to consumer demands evaluating the challenges and opportunities of greening the supply chain. By addressing information asymmetry, aligning incentives, and promoting transparency, stakeholders can leverage agency theory to achieve more sustainable and responsible supply chain management. Critical success factory theory identifies internal and external factors thereby facilitating prioritization, resource allocation, benchmarking, performance improvement, and alignment with overall strategy leading to leadership commitment, supplier integration, and stakeholder engagement. When an organization is newly adapting to GSCM, then diffusion of innovation theory aids in understanding the knowledge, persuasion, decision, implementation, and confirmation of the practice. This influences the organization to tailor the targeted strategies, identify early adopters, and overcome the barriers. The graph theory aids in sustainable sourcing, circular economy strategies, risk assessment, and mitigation. It further propels the organization to optimize its transportation routes through network visualization, data-driven decision-making, and simulating scenarios.

4.3.A. Key Theories on Sustainable and Green Supply Chain Management

Table 7

Key Theories Shaping Sustainable and Green Supply Chain Management Practices

|

Framework |

Author |

Factor |

Researchers who have used the theory in their research |

|

Institutional theory |

Zhu & Sarkis (2007) |

Normative, coercive and memetic |

Dubey et al. (2019) |

|

Fuzzy set theory |

Govindan et al. (2013b) |

Cost, reliability, quality, technology capacity, pollution production, resource consumption, environmental management system, eco design |

Tseng et al. (2015) |

|

Game theory |

Tian et al. (2014) |

This research aims to optimize supply chain performance by analyzing the influence of cost-sharing contracts on product greening, pricing, and profitability. |

Ghosh & Shah (2015) |

|

Coordination theory |

Zhu, Sarkis et al. (2012) |

Successful GSCM requires coordinated internal and external practices, often adopted sequentially. These practices, along with their mediating effects, influence overall effectiveness. Additionally, robust coordination across the supply chain is crucial, encompassing inter-organizational dependencies, product information flow, and intra/inter-organizational activities – all aimed at striking an equilibrium between environmental and economic performance. |

Ahmed et al. (2020) |

|

Grey theory |

Hashemi et al. (2015) |

The factors identified in the research are cost, quality, delivery, technology, flexibility, culture, innovativeness relationship, eco-design, pollution production and control, green competency, consumption of resources, ecological system, green image, management commitment, staff environmental training and green product. |

Bai et al. (2017) |

|

Agency theory |

Wilhelm et al. (2016) |

The limitations a supplier faces in terms of materials, capacity, or technology can influence their negotiating power and willingness to make concessions. Negotiation tactics like leveraging bargaining chips or establishing dominance can influence the outcome. Aligning the goals of sustainability teams and purchasing departments within a company can lead to more focused negotiations. |

Cole & Aitken (2019) |

|

Theory of critical success factors |

Grimm et al. (2018) |

The factors identified in the research are trust between the supplier who is connected directly and the focal firm; Supplier commitment to sustainability; Supplier competence and skills; Language and cultural differences; Supplier collaboration and communication; Supplier transparency and information sharing; supplier compliance with regulations and standards; Supplier commitment to continuous improvement; Supplier risk management; Supplier engagement in sustainability initiatives; Supplier accountability; Supplier performance measurement and evaluation; Supplier innovation and creativity; Supplier adaptability and flexibility |

Grimm et al. (2018) |

|

Diffusion of innovation theory |

Zhu et al. (2007) |

The five stages of innovation adoption are knowledge, persuasion, decision, adoption, and confirmation, the communication channels, and the time factor in the diffusion of innovation. |

Zhu, Tian et al. (2012) |

|

Graph theory |

Faisal (2012) |

Knowledge and awareness: Deep understanding of circular economy principles and customer receptiveness to such practices. Leadership and support: Strong commitment from top management alongside supportive government policies and regulations. |

Moktadir, Rahman et al. (2018) |

4.3.B. Inferred Interpretations of the Theories

Theoretical frameworks such as institutional theory, game theory, and coordination theory provide valuable lenses for understanding the green supply chain management (GSCM). These frameworks facilitate the analysis of factors influencing GSCM adoption, strategic interactions, and coordination within supply chains. Empirical research is pivotal in bridging the gap between theory and practice, leveraging the analytical power of game and coordination theory to understand strategic interactions and coordination. Researchers and practitioners can use these tools to understand the interactions between the customers, suppliers and participants within the organization. Agency theory enables the examination of principal-agent relationships, which is crucial to frame policies, set strategies between the suppliers and the organization as a whole. The diffusion of innovation theory is valuable for studying the spread of GSCM practices within a specific geographical area or an industry.

A rigorous research approach integrates theoretical frameworks with empirical evidence to provide a nuanced understanding of GSCM. Emerging trends, such as sustainability reporting, the circular economy, and digitalization, require a theoretical lens for interpretation. Research findings in GSCM have significant policy implications. By addressing these considerations, researchers can contribute to a more comprehensive and impactful understanding of GSCM, furthering its role in sustainable development.

4.4. Future Research

In addition, a content analysis investigation of the “identified clusters” was conducted to enhance understanding of the insights inside each cluster. For this analysis, papers containing more than 27 citations were chosen. Articles released in 2020, 2021, 2022 and 2023 underwent independent analysis. The rationale behind the splitting of the articles in this study according to the aforementioned standards is:

(i) The latest research articles require more time for citations.

(ii) The latest articles give a more comprehensive picture of the emerging trends.

Based on the review of the latest articles, the emerging trends in the field of green supply chain management are:

• Technological Integration: Advanced technologies like AI, blockchain, and big data analytics are revolutionizing supply chains, boosting decision-making, efficiency, and risk mitigation. This includes exploring the adoption of blockchain in various sectors, applying BDA-AI technologies for environmental performance, and leveraging quick response technology in supply chain strategies.

• Resilience and Risk Mitigation: With increasing disruptions like pandemics and environmental volatility, the critical aspect is building resilient supply chains. Future research directions include studying the impact of disruptions on SC strategies, developing scenario-based models for risk evaluation, and understanding the relationship between resilience and sustainability.

• Regional and Industry-specific Studies: There is a call for more comprehensive studies focusing on specific regions and industries to address localized challenges and opportunities. This includes exploring SC practices in emerging economies, examining the adoption of sustainable practices in different industries, and understanding the dynamics of supply chain relationships within specific sectors.

• Methodological Advancements: Researchers are emphasizing the need for methodological advancements in areas such as structural modeling techniques, multi-criteria decision-making methods, and longitudinal studies. These advancements aim to enhance the applicability of frameworks, validate research findings, and provide a deeper understanding of complex supply chain dynamics.

• Smart and Intelligent Supply Chains: The concept of smart and intelligent supply chains is gaining traction, with a focus on self-correcting systems, intelligent workflows, and the application of AI and deep learning in decision-making processes. This includes studying the role of AI in SCM, integrating smart technologies for enhanced performance, and exploring the implications of AI and augmented techniques.

Supply chain management is undergoing a paradigm shift, driven by a confluence of emerging research areas. Firstly, there is a heightened focus on SSCM, encompassing practices like carbon emission policies, corporate social responsibility, and circular economy principles. Researchers are actively investigating methods for sustainable supplier selection, green integration, and socio-environmental performance assessment. Secondly, technological advancements such as AI, blockchain, and Big Data Analytics are being explored to bolster decision-making, optimize efficiency, and mitigate risks. This includes applications in diverse sectors, leveraging BDA-AI for environmental impact assessment, and integrating blockchain for supply chain transparency. Thirdly, building resilient supply chains capable of weathering disruptions like pandemics and climate change is a critical research frontier. This involves investigating the impact of disruptions on existing strategies, developing scenario-based risk models, and exploring the synergy between resilience and sustainability goals. Fourthly, the need for regional and industry-specific studies is recognized to address localized challenges and opportunities. Research efforts encompass exploring practices in developing economies, examining sustainability adoption across different industries, and deciphering the dynamics of supply chain relationships within specific sectors. Finally, advancements in methodological approaches such as structural modeling, multi-criteria decision-making, and longitudinal studies are being emphasized. These advancements aim to refine the applicability of frameworks, validate research findings, and achieve a more nuanced understanding of complex supply chain dynamics. The integration of these research areas will be instrumental in shaping the future of robust, sustainable, and intelligent supply chain management.

5. Discussion and Conclusion

A systematic literature review (SLR) was aligned with PRISMA guidelines to address predetermined research questions. Using the Scopus database, our initial search yielded 3,397 articles relevant to green supply chain management (GSCM). To comprehensively analyze this retrieved literature, we employed both bibliometric and thematic analysis techniques. The research theme of GSCM has gained significant traction since 1999, with a notable surge in global attention from 2006 onwards. Pioneering research by van Hoek (1999) has garnered 861 citations, establishing him as a pioneering scholar in Supply Chain Management research. But Stefan Seuring stands out as the highly cited author globally, with a combined total of 3,872 citations. China is the most prominent contributor to GSCM research, with 659 publications. The United States (415 articles) and the United Kingdom (373 articles) follow closely behind. VOSviewer analysis revealed eight distinct thematic clusters within the GSCM research domain, each focusing on a specific topic or sub-theme. These clusters are further detailed in Table 6.

The study reveals a mixed impact on economic and environmental performance. While some studies demonstrate positive correlations, others, particularly in specific contexts like Chinese automobile companies, indicate limited or no improvements despite robust GSCM implementation. The effectiveness of GSCM practices varies based on industry context, regulatory pressures, and the specific focus of efforts. Studies emphasize the need for a balanced approach considering social, economic, and environmental factors. Integrating circular economy principles with green practices shows potential, but challenges in supply chain redesign and consumer education persist. The economic benefits of environmental practices are debated, with some research suggesting a sustainable competitive advantage and others finding no significant link. The relationship between environmental and economic goals in supply chain management is complex. While some studies suggest green initiatives can lead to economic benefits, weak regulations in developing countries may limit the adoption of these practices. Regulations play a crucial role, with stricter measures leading to more environmentally friendly supply chain designs. Reputational risk and sustainability practices are key drivers of sustainable supply chain risk management (SSCRM). Sustainability efforts can reduce overall risk, but motivations vary, with some organizations driven by legal compliance and others by stakeholder pressure. Industry-specific risks require tailored risk management strategies. GSCM adoption varies by region and industry. In developing countries, adoption is limited, while in other regions, stakeholders influence sustainability aspects. The impact of GSCM on enterprise performance differs, with inventory control, transportation costs, and the value of recovered materials being critical factors. Government incentives can positively influence green practices, and consumer attitudes towards remanufactured products are generally favorable. However, strategies for sustainable supply chains differ between manufacturing and service sectors. Consumer environmental consciousness is a key driver for green marketing, but aligning organizational practices with market demands presents challenges. Green marketing can lead to competitive advantages and profitability, but integrating it with GSCM faces challenges in information flow and resource allocation. Integrating corporate social responsibility (CSR) with supplier relationship management (SRM) and SSCRM is complex, with factors like top management values, risk reduction, and stakeholder pressure influencing implementation. Effective implementation requires collaboration among stakeholders, especially suppliers. Internal corporate social responsibility practices and government subsidies can positively impact GSCM adoption and overall supply chain performance.

Theoretical frameworks such as institutional theory, game theory, and coordination theory offer valuable perspectives for analyzing green supply chain management (GSCM). These frameworks facilitate the exploration of factors influencing GSCM adoption, strategic interactions among stakeholders, and coordination within supply chains. Empirical research is essential for validating theoretical insights. Game theory and coordination theory provide tools for analyzing strategic interactions and coordination. Agency theory enables the examination of principal-agent relationships, crucial for framing policies and setting strategies between suppliers and organizations. The diffusion of innovation theory is valuable for studying the spread of GSCM practices within specific geographical areas or industries. Emerging trends, such as sustainability reporting, the circular economy, and digitalization, require a theoretical lens for interpretation. Research findings in GSCM have significant policy implications. By addressing these considerations, researchers can contribute to a more comprehensive and impactful understanding of GSCM, furthering its role in sustainable development.

The research gap and future research directions leaned towards the extensive body of literature on GSCM highlighting the need for further theoretical development in specific areas. These areas include the resilience resource model, carbon footprint analysis, reverse logistics, and remanufacturing processes. Additionally, future research could benefit from a more rigorous methodological approach. To enrich the analysis, future researchers could incorporate complementary analytical techniques like meta-analysis, hybrid review techniques, and econometric analysis tools as this approach can contribute towards improved decision-making, enhanced collaboration, and increased transparency among SCM participants. Furthermore, research efforts should prioritize continuous improvement across product, process, and network efficiency, ultimately impacting organization’s overall operational costs.

While GSCM research often relies on quantitative methods like correlation analysis, regression analysis, SEM, factor analysis, and systematic literature reviews (SLRs), this study encourages the exploration of more sophisticated techniques. These include multi-criteria decision-making (MCDM) techniques, t-tests, TOPSIS, and semantic network analysis, data mining, whole interpretive structural modeling (WISM), and comparative case studies. Integrating these methods can enrich the GSCM research landscape, providing a more comprehensive foundation for future studies.

6. Limitations

This study acknowledges some limitations. The chosen keywords might not capture every relevant article, and alternative terms could yield different results and potentially distinct thematic clusters. Additionally, variations in software algorithms and frameworks may influence outcomes. Finally, time constraints during data collection might have excluded some relevant articles published before 1999.

References

Abbey, J. D., & Guide, V. D. R. (2018). A typology of remanufacturing in closed-loop supply chains. International Journal of Production Research, 56(1–2), 374–384. https://doi.org/10.1080/00207543.2017.1384078

Abdallah, T., Diabat, A., & Simchi-Levi, D. (2012). Sustainable supply chain design: A closed-loop formulation and sensitivity analysis. Production Planning and Control, 23(2–3), 120–133. https://doi.org/10.1080/09537287.2011.591622

Abdel-Basset, M., & Mohamed, R. (2020). A novel plithogenic TOPSIS- CRITIC model for sustainable supply chain risk management. Journal of Cleaner Production, 247. https://doi.org/10.1016/j.jclepro.2019.119586

Ahi, P., & Searcy, C. (2013). A comparative literature analysis of definitions for green and sustainable supply chain management. Journal of Cleaner Production, 52, 329–341. https://doi.org/10.1016/j.jclepro.2013.02.018

Ahmed, W., Ashraf, M. S., Khan, S. A., Kusi-Sarpong, S., Arhin, F. K., Kusi-Sarpong, H., & Najmi, A. (2020). Analyzing the impact of environmental collaboration among supply chain stakeholders on a firm’s sustainable performance. Operations Management Research, 13(1–2), 4–21. https://doi.org/10.1007/s12063-020-00152-1

Aria, M., & Cuccurullo, C. (2017). bibliometrix: An R-tool for comprehensive science mapping analysis. Journal of Informetrics, 11(4), 959–975. https://doi.org/10.1016/j.joi.2017.08.007